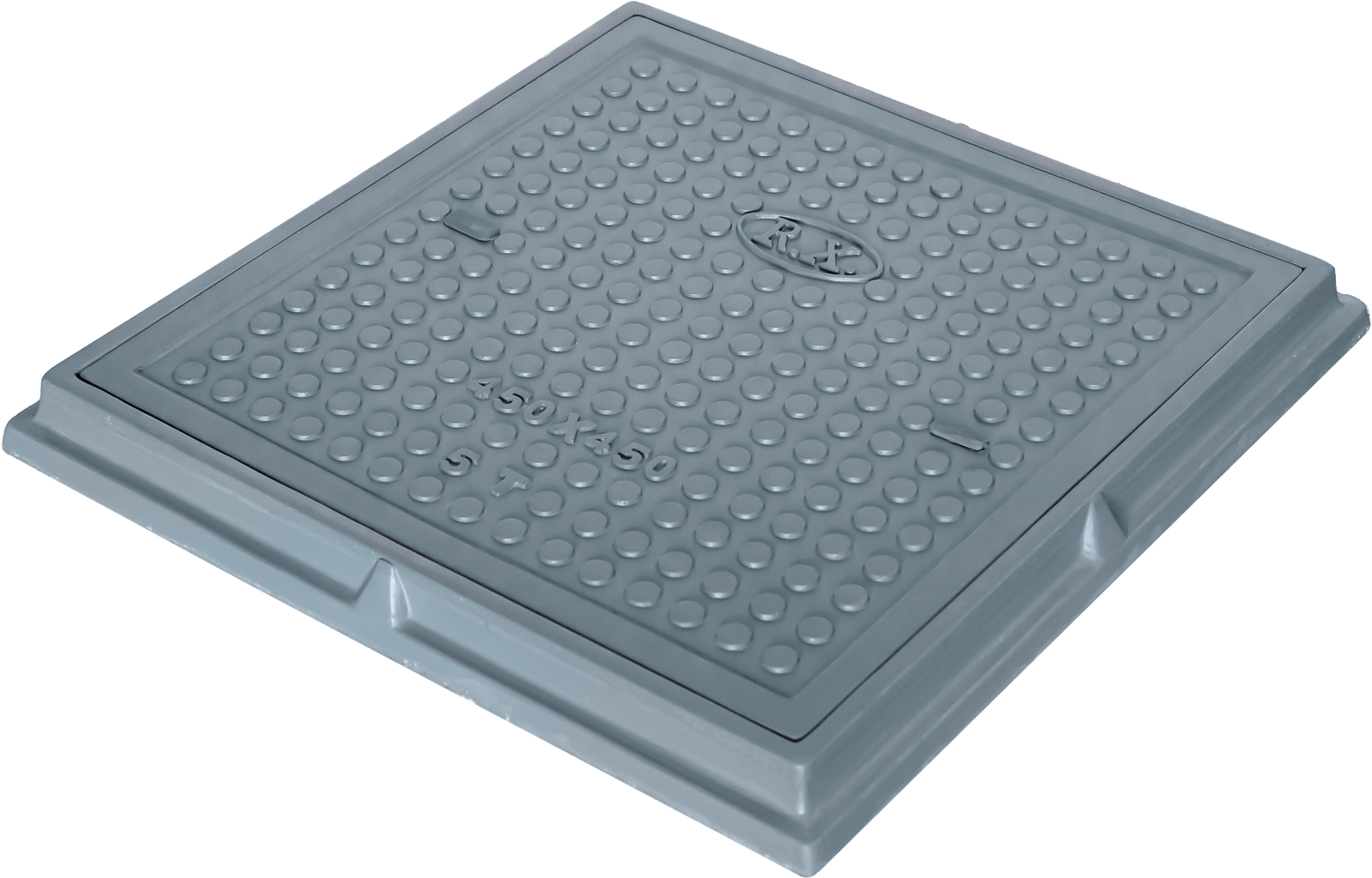

“Default product color is Grey. For other color options, please call us before placing your order.”

RX Industries’ FRP manhole covers are lightweight, exceptionally durable, and corrosion-resistant, making them ideal for urban and industrial applications. RX Industries offers various sizes and shapes, meeting BS EN 124 standards. RX Industries ensures high load capacity, enhanced safety, and minimal maintenance for reliable, long-lasting performance.

| Item | Load | Clear Opening (A) | Cover Size (B) | Frame Size (c) | Frame Height (D) | Cover Thickness (H) | Weight (Kg.) |

| Square | 2.5/5 | 225x225 | 250 | 320 | 40 | 15 | 6 |

| 10/20/40 | 225x225 | 290 | 375 | 50 | 20 | 10 |

| 2.5/5 | 300x300 | 325 | 390 | 40 | 15 | 7 |

| 10/20/40 | 300x300 | 375 | 425 | 50 | 30 | 24 |

| 2.5/5 | 450x450 | 475 | 540 | 40 | 15 | 14 |

| 10/20/40 | 450x450 | 490 | 570 | 60 | 40 | 40 |

| 2.5/S | 600x600 | 640 | 710 | 50 | 25 | 28 |

| 2.5/S | 600x600 | 640 | 710 | 50 | 25 | 28 |

| 10/20/40 | 750x750 | 830 | 930 | 80 | 40 | 90 |

| 10/20/40 | 750x750 | 830 | 930 | 80 | 40 | 90 |

| 20/40 | 900x900 | 1000 | 1120 | 90 | 50 | 110 |

| 40 | 1200x1200 | 1320 | 1440 | 100 | 60 | 130 |

| Rectangle | 2.5/5/10 | 300x450 | 330x480 | 390x540 | 35 | 15 | 8 |

| 2.5/S | 450x600 | 490x640 | 560x710 | 40 | 15 | 30 |

| 10/20/40 | 450x600 | 520x660 | 600x750 | 60 | 40 | 48 |

| 10/20/40 | 450x600 | 520x660 | 600x750 | 60 | 40 | 48 |

| 2.5/S | 450x900 | 510x960 | 610x1040 | 40 | 25 | 46 |

| 2.5/S | 450x900 | 510x960 | 610x1040 | 40 | 25 | 46 |

| 10/20/40 | 450x900 | 520x965 | 615x1065 | 90 | 50 | 75 |

| 10/20/40 | 600x750 | 680x830 | 780x930 | 80 | 50 | 80 |

| 10/20/40 | 600x900 | 680x980 | 780x1080 | 90 | 60 | 100 |

| 10/20/40 | 600x900 | 680x980 | 780x1080 | 90 | 60 | 100 |

| 20/40 | 750x900 | 840x990 | 960x1110 | 90 | 60 | 120 |

| Circular | 2.5/5/10 | 300 | 360 | 460 | 40 | 25 | 13 |

| 20/40 | 300 | 360 | 460 | 75 | 40 | 16 |

| 2.5/5/10 | 450 | 510 | 610 | 40 | 25 | 18 |

| 20/40 | 450 | 520 | 620 | 75 | 40 | 28 |

| 20/40 | 530 | 610 | 710 | 80 | 40 | 47 |

| 2.5/5/10 | 600 | 660 | 760 | 50 | 25 | 30 |

| 20/40 | 600 | 670 | 770 | 80 | 45 | 55 |

Comparison with CI/DI vs SFRC vs RX FRP Manhole Cover

| Description | R.X. FRP | CI/DI | SFRC |

| Life Span | High | Moderate | Low |

| Corrosion Resistance | High | Poor | Medium |

| Thermal Expansion | Negligible | High | Low |

| Strength & Weight Ratio | Very High | Moderate | Low |

| Color Range | Available | Not Available | Not Available |

| Finishing | Excellent | Normal | Poor |

| Customization | Offering | No | No |

| Locking System | Available | Not Available | Not Available |

| Scrap Value | Nil | High | Low |

| Cost | Very High | Moderate | Low |

| Handling | Easy | Difficult | Very Difficult |

| Logo Embossing | Available | Not Available | Not Available |

| Abrasion Resistance | Yes | None | None |

Load Capacities and Gradation as per IS: 1726 (1991) Of Manhole Cover

| Grade | Grade Designation | Recommended Application |

| Light Duty | LD-2.5 (Wheel load 0.8T) | Suitable for use within residential boundary, walking pathways, pedestrian areas, and pedal cyclists. |

| Light Duty | LD-5.0 (Wheel load 2.5T) | Recommended for areas with light motor vehicle traffic (less than 3 tons), basement parking, and parking decks in residential areas. |

| Medium Duty | MD-10 (Wheel load 3.0T) | Areas such as service lanes/roads, on pavements with medium-weight motor vehicle traffic, including car parking. |

| Heavy Duty | HD-20 (Wheel load 5.0T) | Suitable for use in city trunk roads, bus terminals, and areas where heavy-duty motor vehicle traffic, cul-de-sacs, and frequent traffic areas are present. |

| Extra Heavy Duty | EHD-40 (Wheel load 11.5T) | For high-density traffic areas and all types of vehicles like loaded trucks, containers, and trailers up to fire tenders. Suitable for industrial parks, warehouses, godowns, roads (main, sector, and national highways). |

Load Testing Of Our Frp Manhole Cover

FRP/GRP/COMPOSITE products are tested for LD (2.5/5 Mt), MD (10 Mt), HD (20 Mt), and EHD (35 Mt and above) load-bearing and permanent set as per BS EN: 124, IS: 1726 (1991). BS EN: 124 is a testing code worldwide for manhole covers in cast iron, ductile iron, and other materials.

Permanent Set is a multiple loading test to determine the permanent deformation in covers after multiple loading within a short time as specified in the code.

We have an in-house testing facility where we conduct regular tests batch-to-batch for quality consistency in the product.

Physical Characteristics Of Frp Manhole Cover

| Characteristic | Details |

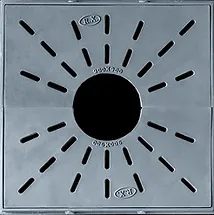

| Shape Available | Circle, Square, Rectangle, and Customized |

| Working Temperature | -10 to 120 degrees Celsius |

| Noise | Reduced noise and vibration |

| Conduction | Non-electricity and heat conduction |

| Color | Standard gray (customization available) |

| Surface Treatment | Anti-slip, anti-UV |

| Technique | Mold Pressing |

| Packing | Cardboard or as per customer's need |

Technical Specification Of Frp Manhole Cover

| Description | R.X. Manhole Cover Performance |

| Longitudinal Strength | 250 - 600 MPa |

| Compressive Strength | 300 - 600 MPa |

| Stretch Modulus | 25 - 35 GPa |

| Break Elongation Ratio | 1.3 - 10.0% |

| Bending Strength | 700 - 1400 MPa |

| Poisson's Ratio | 0.35 |

| Relative Density | 1.11 - 1.15 |

| Water Absorption (24h) | 10 - 30 mg |

Reviews

There are no reviews yet.