Gfrp bar |Frp Rebar | GFRP Bars

| FRP Rebar Gfrp Rebar Glass Fiber Reinforced Polymer Bars |

Are you searching for a superior alternative to steel reinforcement that delivers unmatched corrosion resistance, exceptional strength, and long-term cost savings? Our GFRP rebars—also known as FRP rebars, fiberglass rebars, or glass fiber reinforced polymer bars—are engineered to meet the demands of modern infrastructure while addressing the shortcomings of traditional steel reinforcement.

Starting From ₹1050

FRP Rebar Circular (14 mm, 12 mtr) – ₹1050 via Add to Cart. For other options, Call or WhatsApp us.

What Are GFRP Rebars / GFRP Bar ?

GFRP rebars (Glass Fiber Reinforced Polymer) are non-metallic reinforcement bars made by combining high-strength glass fibers with a polymer resin matrix. This advanced material technology results in rebars that are strong, lightweight, non-corrosive, and thermally non-conductive. These characteristics make GFRP rebars an ideal solution for a wide variety of applications, especially in environments where corrosion is a major concern.

Also known as FRP rebars or FRP reinforcement bars, they offer a forward-thinking alternative to steel, ensuring enhanced durability, reduced maintenance, and greater structural longevity.

Key Benefits of FRP Rebars / GFRP Rebars

Switching to FRP bars can provide significant advantages across the lifecycle of your project. What makes them a great option is as follows:

✅ Corrosion Resistance

One of the key benefits of GFRP rebars is their resistance to rust and chemical damage. Unlike steel, which deteriorates over time in moist or chemically aggressive environments, fiberglass rebars maintain their structural integrity, making them ideal for use in marine settings, wastewater plants, and coastal construction.

✅ Lightweight for Easy Handling

Because FRP rebars are over 80% lighter than steel, labor and shipping expenses are greatly decreased. On-site handling becomes easier and faster, allowing for quicker project completion and reduced manpower requirements.

✅ High Tensile Strength

Despite their lightweight nature, GFRP bars offer excellent tensile strength. In fact, the tensile strength of FRP rebars is higher than that of conventional steel, enabling them to perform under high-load conditions while offering structural safety and stability.

✅ Electromagnetic Neutrality

FRP rebars do not interfere with electromagnetic fields, making them suitable for sensitive environments like power plants, MRI rooms in hospitals, and research laboratories.

✅ Non-Conductive and Thermally Stable

GFRP rebars are non-conductive and thermally stable, which helps prevent the formation of thermal bridges. This makes them a preferred choice in cold storage units and facilities where temperature regulation is critical.

Applications of GFRP Bars and FRP Rebars

Whether you are constructing critical infrastructure or private residential projects, FRP rebars are versatile and dependable. Typical applications include:

- Bridge decks and highway pavements

- Marine piers and seawalls

- Parking structures

- Water treatment plants

- Swimming pools and aquariums

- Tunnels and underground structures

- Foundations in corrosive soil environments

- Airport runways and aprons

- Industrial floors with high chemical exposure

GFRP Rebar Price / FRP Rebar Price– Competitive & Cost-Effective

When evaluating GFRP rebar price or FRP rebar price, it’s essential to consider not just the initial cost but also the long-term value. Our fiberglass rebar pricing is designed to provide maximum performance while being budget-friendly.

While the upfront price of FRP bars may be slightly higher than steel, the savings in terms of reduced maintenance, no rust-related repairs, and longer service life far outweigh the initial investment. We offer flexible pricing for bulk orders and project-specific customizations. For the most accurate and up-to-date GFRP bars price, please contact our sales team directly.

We provide detailed quotes based on your project scope, required dimensions, and delivery timeline.

Why Buy GFRP Rebars / GFRP Bar From Us?

We are the best Gfrp Bar and Frp Bar Seller across the country That is why engineers, contractors, and project managers across the country trust us:

- Premium quality, certified products

- Custom lengths and diameters available on request

- In-house technical support for design and implementation

- Fast and reliable delivery across India and globally

- Bulk order discounts and project-based pricing

- Over 100+ satisfied clients across infrastructure, marine, and residential sectors

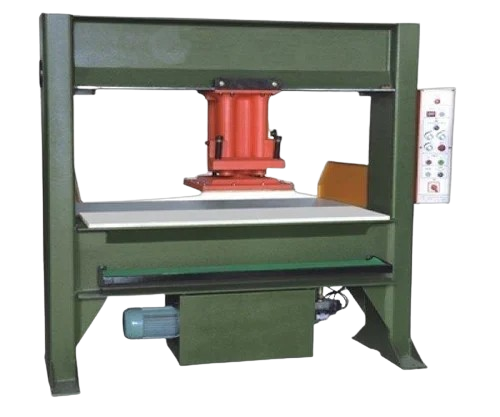

Load Testing GFRP Rebar / FRP Bar

FRP/GRP/COMPOSITE products are tested for LD (2.5/5 Mt), MD (10 Mt), HD (20 Mt), and EHD (35 Mt and above) load-bearing and permanent set as per BS EN: 124, IS: 1726 (1991). BS EN: 124 is a testing code worldwide for manhole covers in cast iron, ductile iron, and other materials.

Permanent Set is a multiple loading test to determine the permanent deformation in covers after multiple loading within a short time as specified in the code.

We have an in-house testing facility where we conduct regular tests batch-to-batch for quality consistency in the product.

Speak to Our Team – Request a Quote Today

Whether you need a few bundles or a bulk supply for large infrastructure, our team is ready to assist you. We’ll help you choose the right FRP rebars, offer technical guidance, and ensure you get the best fiberglass rebar price available in the market.