Frp Slot Drain

Slot Drain

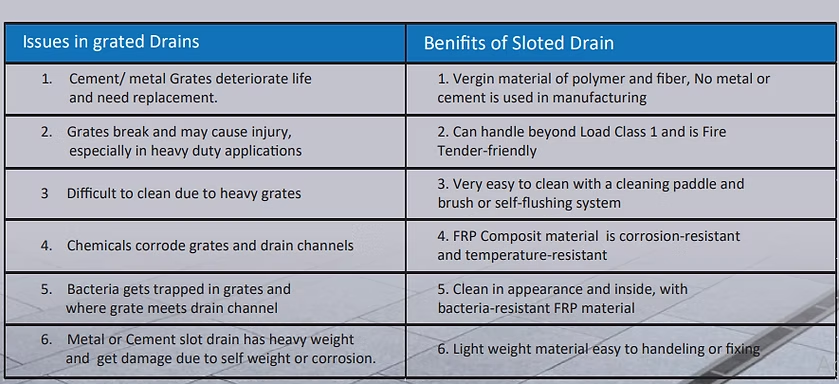

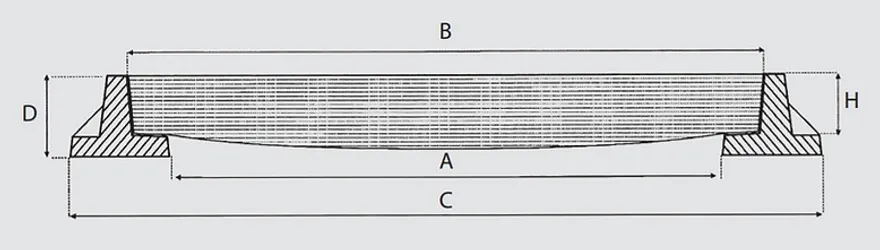

R.X. FRP Slot Drain system is designed for numerous market sectors. Slot Drain is made to suit your special requirements. Slot Drain provides drainage solutions that are durable, sanitary, aesthetically appealing, easy to clean, load class rated, corrosion and temperature resistant and odour eliminating. Slot Drain System is Smart, Simple, Safe Drainage Solutions for surface drainage project and offering drainage solutions that are as effective as aesthetically pleasing. Uses : It can be used in farms, warehouses, factories like food and beverage manufacturing facilities, homes, poolsides, slaughterhouses, aquariums, car washes, and automotive facilities areas. FRP Slot Drain Sizes : 115 x 100 mm with 45 mm recessed height. * Basically the slot drain costumizes as per reuirement of costumer in different sizes and designed.

Physical Characteristics Frp Slot Drain

| Characteristic | Details |

|---|---|

| Shape Available | Circle, Square, Rectangle, and Customized |

| Working Temperature | -10 to 120 degrees Celsius |

| Noise | Reduced noise and vibration |

| Conduction | Non-electricity and heat conduction |

| Color | Standard gray (customization available) |

| Surface Treatment | Anti-slip, anti-UV |

| Technique | Mold Pressing |

| Packing | Cardboard or as per customer's need |

Technical Specification Frp Slot Drain

| Description | R.X. Manhole Cover Performance |

|---|---|

| Longitudinal Strength | 250 - 600 MPa |

| Compressive Strength | 300 - 600 MPa |

| Stretch Modulus | 25 - 35 GPa |

| Break Elongation Ratio | 1.3 - 10.0% |

| Bending Strength | 700 - 1400 MPa |

| Poisson's Ratio | 0.35 |

| Relative Density | 1.11 - 1.15 |

| Water Absorption (24h) | 10 - 30 mg |

Load Testing Frp Slot Drain

FRP/GRP/COMPOSITE products are tested for LD (2.5/5 Mt), MD (10 Mt), HD (20 Mt), and EHD (35 Mt and above) load-bearing and permanent set as per BS EN: 124, IS: 1726 (1991). BS EN: 124 is a testing code worldwide for manhole covers in cast iron, ductile iron, and other materials.

Permanent Set is a multiple loading test to determine the permanent deformation in covers after multiple loading within a short time as specified in the code.

We have an in-house testing facility where we conduct regular tests batch-to-batch for quality consistency in the product.